Why Nobody Cares About Sheet Metal Storage Until…

Most fabricators, OEMs, and manufacturing companies would be the first to admit that sheet metal storage is NOT one of the most critical aspects of running an efficient and profitable operation. But why do so many leaders in these companies fail to even consider their storage needs until it’s too late?

The businesses that see their margins consistently rise from one quarter to the next are those that get ahead of this issue by considering all the ways sheet metal storage can bolster everything from day-to-day ops to long-term scalability.

Here are just a few of the most common such instances in which leaders learn that it’s already too late to start planning their sheet metal storage strategy. Make sure your operation doesn’t neglect your sheet metal storage until it is too late.

… There’s No Space for New Equipment

We’ve seen it countless times. Your business is booming and you want to add some new equipment to help keep up with demand. The only issue is: you don’t have anywhere to put the latest and greatest equipment because there’s sheet metal all over the place and nowhere to move or store it. Now, you only have a few options: reorganize your existing space, expand the size of your facility (tying up a lot of time and money), or find a new manufacturing space altogether (again tying up significant amounts of cashflow).

If this all sounds like one big headache waiting to happen, then we’re on the same page.

Luckily, reorganizing existing space often proves to be the most effective solution from a cost and timing standpoint. Take your sheet metal storage for example. Take a real hard look at how much space it is currently consuming in your facility. Don’t worry, I’ll wait – I know it might take a minute.

Hindsight is always 20:20. Plan ahead with a smart, space-saving sheet metal storage solution that gives you more than enough room to add the equipment you need to improve the quality of your product and the efficiency of your production.

The decision seems pretty simple to us thanks to our safe, organized, high-density sheet metal storage solutions built to work perfectly alongside and integrate with you production equipment.

… You’ve Lost Track of Your Inventory

So demand is climbing and you need to increase supply to keep up. Not having anywhere to put your new material was already an issue, but now you’re ordering new material you didn’t even realize you already had. Be honest, how many times has this happened to your team?

There is a better way!

When all of your sheet metal has a dedicated location, adding and consuming inventory becomes much less of a hassle, making it easier for your team to do what needs to be done.

… It’s Time to Move Facilities

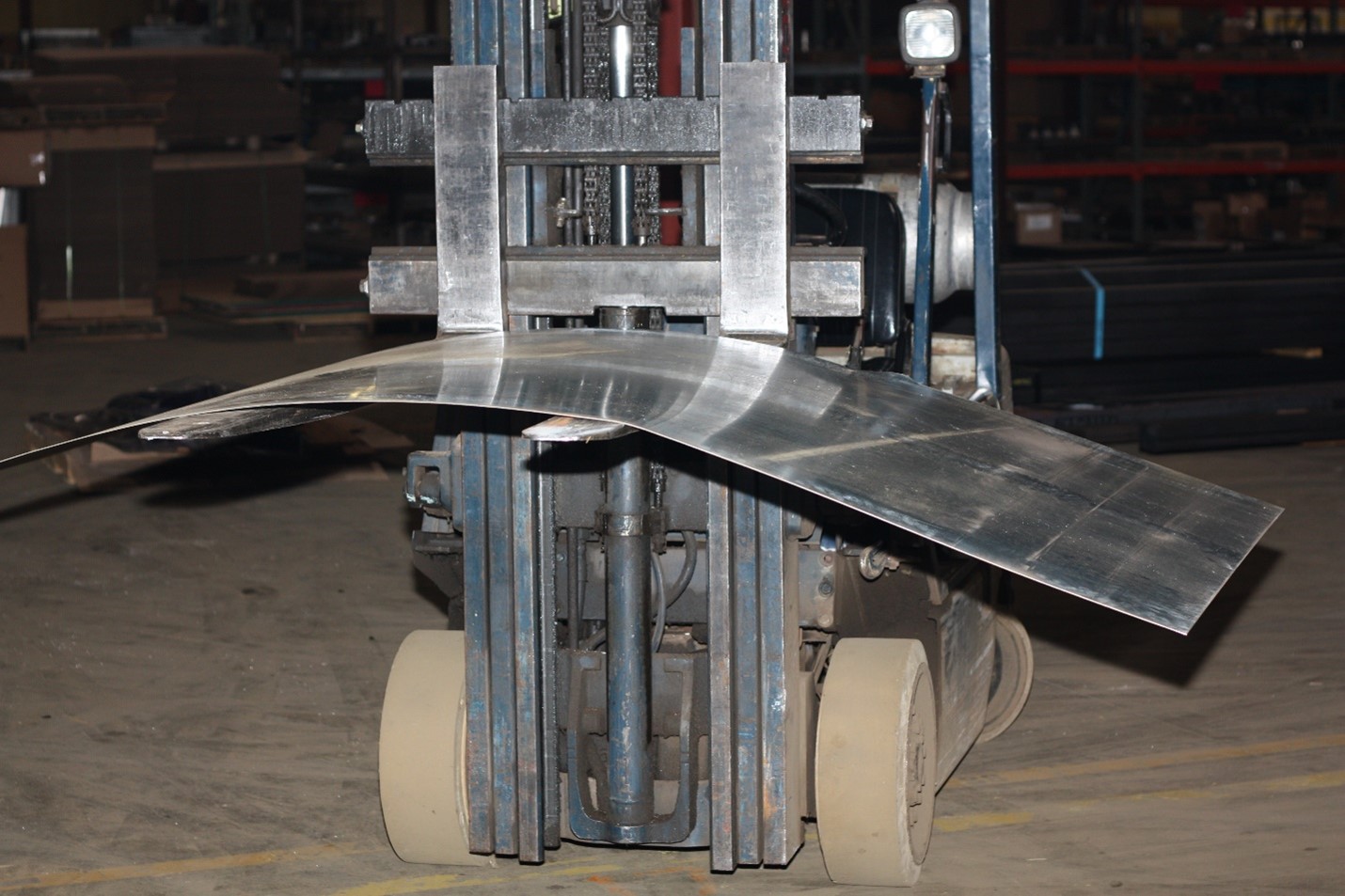

Remember when we said business was booming? Well now, you’re growing at such a rapid rate that it’s time to move to a bigger space – but what are you going to do with all your sheet metal? It’s scattered all over the place, isn’t well-organized, and a lot of it has even gotten damaged in the shuffle of everyday operations. Now you have to corral the salvageable sheets and find a way to transport them efficiently to your new facility – all without damaging or losing track of any material in transit.

Now is the perfect time to be intentional about your material storage. Be intentional about your process flow and about making the most out of every square foot in the new facility. No need to get fancy or break the bank on a fully automated tower system if you aren’t running 24/7.

Just invest in safe, simple, single-operator solutions designed to meet your sheet metal storage needs and keep your new facility organized.

Utilize our Big Steel Rack – sheet metal rack systems and tools like depalletizers, pallet carts, and drop racks. No more drooping sheets on forks and no more exposed sharp edges and corners.

Big Steel Rack is the Solution

Our sheet metal storage solutions make easily and quickly locating material part of the daily routine. Our racks are built at a positive camber so they sit flat when fully loaded, with angled corners that don’t bind up like a 90-degree corner would.

Our racks create more space in warehouses by increasing vertical storage and storage density, upping your storage per square foot and eliminating mixed piles of material from your inventory forever. With our numbered grid system and intelligent design, simplified storage, inventory counts, and transportation are ready to become the SOP.

Contact us today to get started building the perfect storage solution for your business.

Have questions or comments about your operation’s lean processes? Drop us a line below to let us know!